The continuous still (aka: column still, patent still, Coffey still) is a more modern design for spirits production. Instead of a batch process like the pot still, the column still is continuously supplied with fresh wort with an output of freshly-distilled spirit and spent wash.

The column still is capable of producing purer spirits with higher alcohol content. A range from 90% to 95% abv is common. Extra dilution is required to reach bottling strength resulting in less flavor from the ingredients/wash.

Column Still Design and Function

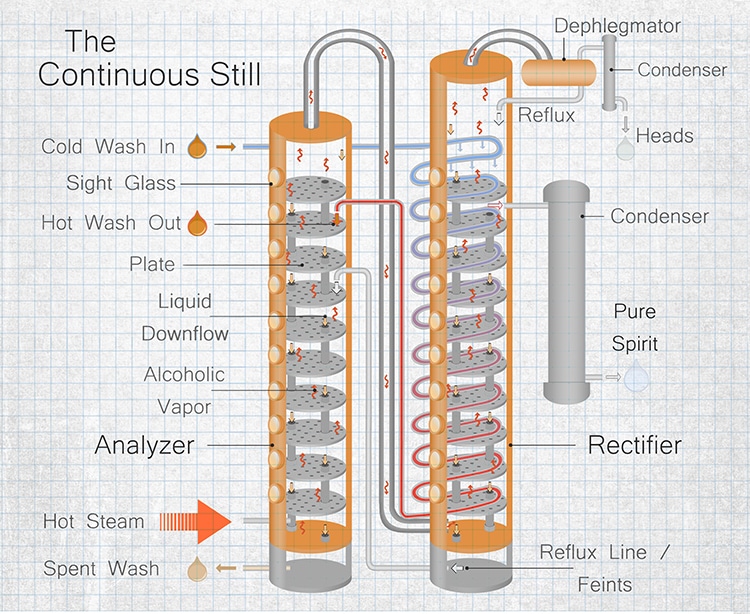

A column still, not surprisingly, is relatively narrow and tall. A single column design will feature a boiler at the base producing steam, a lower stripping section where the wash goes, and an upper rectifying section where alcohol levels increase.

The final spirit is collected after it passes through a condenser at the top.

Inside the column is a series of plates. The plates hold the wash but allow vapor to pass through. The vapor increases in alcohol content as it travels upwards through the analyzer and rectifier.

Simultaneously, the wash is stripped of its alcohol and flows downward through downflow tubes in the plates. Wash strength reduces as it flows downward. A continuous cycle of alcoholic wash can be pumped into this type of still, creating a continuous outflow of spirit and spent wash.

Multiple Column Still

When two columns are used, like in the original Coffee still, the first column acts as the stripping section (Analyzer). The alcoholic vapor from the analyzer enters the bottom of the rectifying column, where the finished spirit is ultimately collected.

When a high purity spirit is desired, more than two columns can be used. The resulting spirit can be as high as 96.5% abv. This is ideal for neutral spirits like vodka.

Column Still Whisky

Whisky made from a continuous still is typically lighter than from a pot still. It is often used to make lower-end whiskies, lighter components of blends, and grain whisky.

Column stills are also often used to distill bourbon. This distillation run is followed by a second in a pot still “doubler” or sometimes in the similar “thumper.” A thumper uses water to sparge the initial distillate and refine its character.