Last Updated: 2/12/2021

Without oak aging, there is no whisky. Bottled spirit won’t develop into whisky with age. It will remain basically the same. Storage in wood is essential to convert clear, grain-based spirit (new make) into its final form. So it makes sense that oak barrels would have a huge impact on the character of whisky.

But why?

That’s what this oak-centric article attempts to answer. There is no singular factor that determines an oak barrel’s influence on whisky. Below we’ll get into the many variables of time, barrel treatment, types of oak, climate, storehouses, and more. It sounds more complex than it really is though, so let’s dive in!

Characteristics of Oak

The vast majority of the wood used for barrel-aging whisky is oak (genus Quercus). More specifically: the heartwood portion is used. It’s strong but permeable. The liquid will generally not leak. Despite this, oxygen is able to pass in and out, and evaporation is able to escape the barrel.

The heartwood has several structural properties that impact the barrel and the whisky (or whiskey) inside.

One of the major components of oak heartwood is hemicellulose. This polysaccharide is present in most plant cell walls, but Quercus has an abundance of it. Hemicellulose is composed of ten types of sugars that have a low molecular weight. This allows them to dissolve is alcohol easily adding flavor and complexity to the whisky.

Another important organic compound found in oak barrels is cellulose. It’s where much of the rigidity and durability comes from. The wood is flexible, but can keep its shape for decades.

A third key component is lignin. It’s a class of polymers that’s important for the formation of cell walls. Lignin acts like the glue that holds the cellulose fibers together, increasing rigidity. It also doesn’t rot easily which further enhances durability.

Lignin features two important organic compounds: vanillin and syringol. They both impart aromatics of vanilla in whisky and are water soluble. Syringol is also noteworthy for producing a smoky aroma. It’s a major source behind the smell of burning wood. None of this will surprise whisky drinkers.

The final major components of oak heartwood are less abundant yet still important. Oak tannins are something wine enthusiasts are familiar with. Astringent tannins have a similar effect on whisky by providing bitterness. Tannins soften and develop with time into a more pleasant attribute.

Lactones are also present in small amounts and contribute a coconut flavor.

Lastly, there are hundreds of volatile phenolic acids that have their own specific aromatic and flavor profiles that can add to the final whiskey.

Collectively, these structural components of oak store, enhance, and change whisky over time.

Processes of Whisky Maturation – Oak Barrel Aging

Whisky is greatly affected by its time in barrel. This is due to a variety of factors. Collectively, they’re responsible for many of the characteristics that make the drink so special.

Let’s begin by piggybacking off the previous section. Oak has many flavor characteristics that, after heating, are readily released into whisky it comes into contact with. The alcohol/water solution absorbs the congeners, vanillin, syringol, lactones, sugars, etc. that are present in the wood. This extraction process results in many of the classic tasting notes in whisky. The charred, reddish-hued wood also gives the whisky color.

Additionally, oak barrels are toasted or charred and develops a charcoal-like surface. This effectively filters many of undesirable congeners like activated charcoal would. Stripped of many aldehydes and Sulphur compounds– the whisky becomes smoother.

The above two characteristics act independently in the oak aging process. The affects of the porous barrels, oxygen contact, and evaporation are tied together. Together they change the new make into whisky in a number of ways.

The most well-known variable is probably evaporation. Annually, about 3% of the total liquid is lost per year. This rate varies from a low of about 1 or 2% with French oak and a cool climate to up to 10% with American oak in a hot storage environment.

Humidity will affect the ratio of alcohol to water evaporation. Humid environments will see more alcohol evaporation and a reduction of strength. A dry location will have more water loss than alcohol and an increasing strength over time. This loss of whisky due to evaporation is called the angel’s share.

Losing liquid through evaporation has another impact on the whisky inside the oak barrel: concentration. The remaining components in the liquid are intensified leading to richness and a more pronounced flavor profile.

While evaporation and concentration is happening– oxygen is having an impact on the concentrating whisky. It enters the barrels and the liquid freely. The compounds in the whisky like tannins are softened and evolve.

Over time additional esters, aldehydes, and other flavor components develop due to oxidation. This process also darkens the reddish color imparted by the wood and adds a golden coloration. This ultimately makes whisky look brown. Oxidation won’t happen readily in a sealed bottle. So once a spirit is bottled: the processes of maturation effectively ends.

Once again, all of these factors combined shape whisky and make it unique. Without the oak– there is no whisky! Time and the barrel itself are the ultimately variables in the finished product.

Recommended Whisky Products

As an Amazon Associate I earn from qualifying purchases.

Types of Oak and Whisky Barrels

Oak is a member of the beech family within the Quercus genus. There are around 500 species native to the Northern Hemisphere. Of these, only a few are principally used for the production of barrels and casks. They all belong to the white oak subgenus Leucobalanus.

Each species has its own characteristics. And furthermore: where the tree grows will also have a large impact on its character and the resulting barrel. Cooler climates will produce slower growth, tighter growth rings, and stronger wood for example.

American White Oak Whisky Barrels

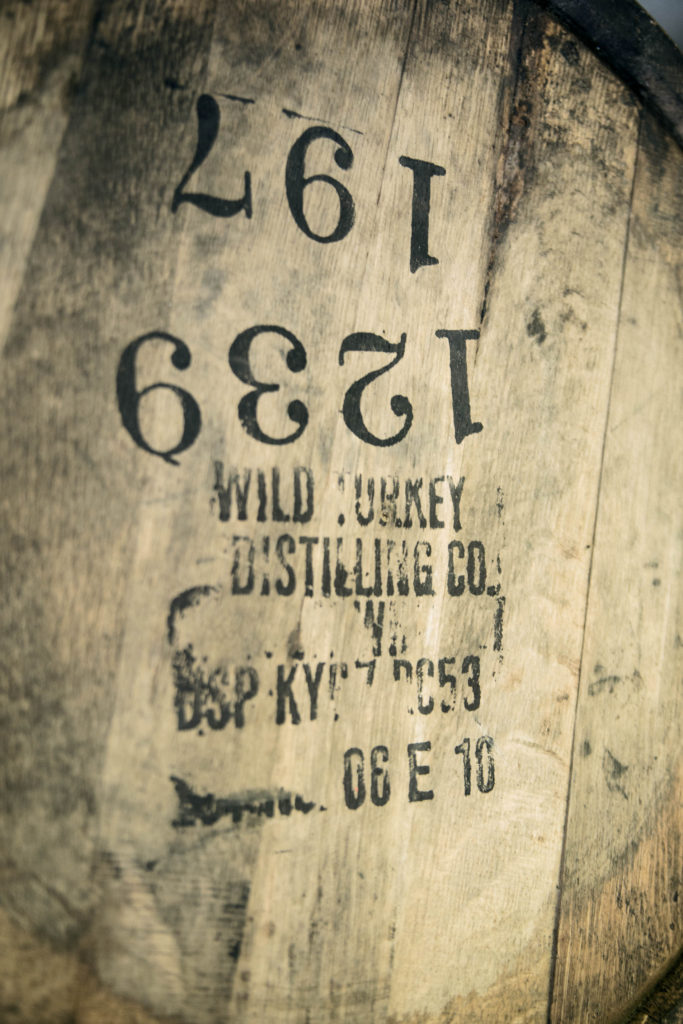

American Oak dominates the spirits industry. This results from the requirement that Bourbon use only new casks and its general abundance.

Quercus alba is the primary species utilized for making barrels. It’s mainly harvested in the Ozarks, the upper Midwest, and the Appalachians. Growth is rapid compared to other major species in barrel production.

American oak, though site-specific, is generally known to have looser grains, wider growth rings, and more tannins than typical European oak species. It also allows for more evaporation. This leads to more oxidation as well and darker flavors.

Some common tasting markers for whisky aged in American oak: vanilla, cinnamon, coconut, dill, and brown sugar. It’s also characterized by a more intense nature than its European counterparts.

Quercus garryana, Oregon oak, has also emerged as a new alternative to alba. Garryana barrels produce a similar profile, but with a darker, fruitier character.

European Oak Whisky Barrels

Two species of European white oak are most commonly used for cask production: Quercus petraea (sissile oak) and robur (pedunculate oak). Oak from France dominates the market, though it is harvested in Eastern Europe, Northern Spain, and Ireland as well.

France has five official forests where oak is harvested: Limousin, Tronçais, Nevers, Allier, and Vosges. The wood from Limousin oak is some of the most expensive used in the spirits industry, new barrels can cost as much as $5K US.

European white oak tends to be more porous than American white oak and is slower growing. It also allows less evaporation, leading to slower maturation. Whisky can get further inside the wood of European oak where it can extract more aromatic and flavor components.

European oak is often associated with notes of dried fruit, dark chocolate, savory spices, and coffee beans. Overall, European oak is well-suited for producing an elegant profile.

Mizunara Japanese Oak

Japanese ‘Mizunara’ is the hottest word in whisky right now. The expensive, slow-growing Quercus mongolica var. crispula is used. The rarity and high cost of their barrels can be attributed to several factors.

One of the main issues is that the tree doesn’t grow straight and needs to be at least 200 years old before it can produce quality wood staves.

Even then, Mizunara’s high moisture content makes it difficult to work with.

Lastly, this Japanese white oak is porous and leaky. It had long been regarded as inferior to American and European white oak for these reasons– until recently.

Suntory has been working with Mizunara for decades, though on and off. Their Hibiki and Yamazaki brands rely heavily on the use of Mizunara to achieve their signature profiles.

It’s safe to say that these mega-popular whiskies have fueled the rise of this rare oak. But even Suntory struggles with supply. That fact hasn’t been helped by demand overseas. Many Scotch producers have been using Mizunara casks more frequently with great success. And Bainbridge Organic Distillers’ “Yama” has racked up numerous high-level awards for its Mizunara-aged grain whiskey.

Classic markers for Mizunara include sandalwood, an aloe-like incense (kyara 伽羅), and coconut. Vanilla, fresh fruit, honey, and spices like clove and nutmeg are also common tasting descriptors for Japanese white oak. It’s said that Mizunara needs a minimum of several years to give up its aroma and flavor components.

Cask Finishing Whiskies

A great variety of barrels and casks are used to mature whisky across the globe. Many times barrels house some other alcoholic beverage before being filled with whisky. The whisky often spends its entire maturation period in one of these barrels.

It’s also common practice for mature whisky to be finished in a used barrel in order to impart some of the character from its original occupant. This is commonly called “cask finishing” or “barrel finishing”.

Sherry casks are a favorite for barrel finishing whisky. The unique wine region in Jerez, Spain has long favored American white oak. The casks they use are ancient, not new. Producers rarely give up their barrels, and these barrels have lost the flavor of the wood anyway.

Sometimes new wood will be used for fermentation of Sherry and then sold to whisky producers. But typically, the much-adored Sherry casks used for whisky maturation are a little different. Specialty coopers season new barrels with Sherry before shipping them off to the market. Casks are typically 500 liters. American oak, Spanish-grown robur, and other types of barrels may be used. These casks will have qualities from the type of Sherry used and the new wood.

The use of these specialty Sherry casks to finish whisky adds additional flavors. There are many types of Sherry with a range of tasting profiles. Drier styles like Fino and Amontillado have less color, are more citrusy, oxidative, briny, and nutty. The (often) sweeter styles like Oloroso or Pedro Ximenez tend to add more color and darker fruit notes.

Other fortified wines like Madeira and Port are also commonly used for cask finishing. Madeira can impart notes like orange peel, honey, and caramel. Port is well known for it’s ruby to purple color sweetness, spice, and dark fruit flavors. Both of these wines are not singular in nature and have variations in styles and flavor leading to a diversity of individual profiles.

There are so many other types of barrels that are used to finish whiskies. Red wine casks from around the world are often used for cask finishing. Honeyed, gingery Sauternes is also highly prized. Barrels that have stored it can fetch a high price. Other cask-aged beverages used to finish whisky include: other types of whisky, rum, Tequila, IPA, shochu, and even sake.

Other Whisky Barrel Considerations

A few other factors also add spice to the topic of whisky barrels. A primary choice a producer will face is the newness of the wood for aging.

New white oak barrels are loaded with compounds that will flavor a whisky. With time, these flavoring components will be reduced. If given enough time storing alcohol– a barrel will become neutral. Some whiskies, like Bourbon, require new oak. Many rely on a mix of new and used (1st fill, 2nd fill, etc.) casks.

Before oak staves are made into a barrel, they must first be dried. The drying of the wood for whisky barrel production is called “seasoning”. The wood needs time to dry out, which also helps it give up unwanted, harsh (rubbery, bitter) compounds. Air drying will produce better results.

A year is a typical minimum, and examples of two or three years of seasoning are not uncommon. Kiln-dried wood is more common due to its speed. The downside is increased astringency and acrid notes.

During the construction of barrels, they will be toasted or charred inside to activate the wood and enhance its impacts on the whisky inside.

The amount of char is often rated #1 through #4, with the latter being dubbed “alligator char” for the rough, shiny texture that develops on the wood’s surface. Higher levels of char do occur but aren’t common.

Climate, Storehouses, and Whisky Aging

The effects of temperature and humidity have already been discussed briefly in this article. These variables have a significant impact on the development of whisky inside of the cask. So it makes sense that where and how a cask is stored would be important.

Cooler climates tend to lead to slower, but more elegant aging. Warmer climates will increase evaporation leading to more intensity more rapidly.

The humidity dynamic will influence the speed at which water or alcohol evaporates in the solution. More humidity means alcohol will evaporate more easily, whereas a drier environment will encourage the evaporation of more water.

These environmental dynamics play out famously across the whisky world. Scotland is well-known for its cool, maritime climate. There whisky will mature more slowly.

Frigid Hokkaido, home to the famous Yoichi distillery from Nikka also induces slow maturation. On the other end of the spectrum are places like Kentucky. Winters are cold, but short-lived. Summers are very hot and humid and whiskey will mature more rapidly in that environment.

Another variable is the storehouse itself. Single story warehouses are common in Europe. They tend to have less variation in temperature inside. Inversely, boubon rackhouses are common and can be up to 10 stories tall. The temperature variance between the top and bottom can be significant.

Lastly, spacing in between barrels can be significant. Are they stacked on top of each other– or can air pass readily in between? More space between barrels, like in many rackhouses, will lead to faster evaporation and maturation.

Sources and Recommended Links

There were a variety of sources used to compile this whisky basics post.

The most important source for me has been my Certified Specialist of Spirits education through the Society of Wine Educators. Their Certified Spirits Educator certification program is another level up and one that I aspire to complete. I highly recommend this educational guild for spirits enthusiasts of all kinds.

Other Sources and Links

These sources and links are great resources to take dive deeper into the subject of whisky and oak. They helped me to learn, and they may help you as well.

List of Quercus Species, Oak, Quercus robur, Quercus petraea, and Quercus crispula. Wikipedia.

George Koutsakis (6/28/2017). The Wonders of Japanese Mizunara Oak. Dekanta.

(11/2/2019). Why you need Japanese Mizunara Oak Casks. Whisky Intelligence.

(11/13/2019). All About Mizunara Wood. Cask Solutions by Ethimex.

(4/13/2018). The Difference Between American and French Oak. Grand Cata

An Original Approach to Wood. Glenmorangie.

Native Oak Series – Garryana Edition 3/1. Westland Distillery.

Alan Tardi (5/4/2020). What Are Wine Tannins?. Wine Folly.

David Broom (2014). Whisky – The Manual. Octopus Publishing.

National Library of Medicine. 4-Methoxyphenol. Pub Chem.

(9/12/2016). Vanillin. American Chemical Society.

(6/31/2015). Syringol. American Chemical Society.

(9/27/2010). Whiskey lactone. American Chemical Society.

Paula Maclean. The Story of the Sherry Cask. El Consejo Regulador de vinos de Jerez y Manzanilla.

(4/3/2016). The Truth about Seasoned Wood. Bourbon Truth.

Related Whisky Posts

- The Japanese Whisky Guide: Understand the Market, History, Popular Brands, and the Brands to Avoid

- The Top 8 Japanese Whiskies Under $100: No Fakes or Koji Whisky

Follow the Japanese Bar on Social Media

Connect with our latest posts, the newest Japanese beverage info, and get exclusive promotional offers. Level-up your Japanese whisky IQ!